How to stop a metal roof sweating - 5 key points to solving your shed condensation problem

A metal roof 'sweating' is a result of excess humidity condensing on the underside of your roof. Metal roofs are known for this, with condensation forming particularly at the beginning and end of a day. The prime reason for this is due to the temperature differential between the inside and the outside of the shed.

There are several methods that can be designed in to a shed (and occasionally retrofitted!) to reduce the incidence of metal roof sweating.

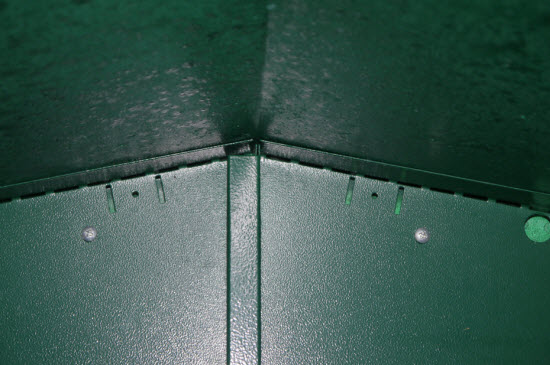

Underside of a corrugated metal roof 'sweating'

Underside of a corrugated metal roof 'sweating'

In this article I will go through each of these ways and then show how some of them apply to a metal shed that I own. Which, despite having occasional condensation problems copes remarkably well.

The five key points to stop your metal roof sweating are

Good roof ventilation

The key to getting condensation to evaporate is air flow. Having ventilation holes around the roof at eaves level and in the gable walls allows moisture rich air to escape. Having vents in all elevations of the shed is an effective way of minimising metal roof sweating.

Roof pitch

The lower the pitch of a metal shed roof and also the deeper the corrugations the worse the problem of metal roof sweating. A low roof pitch (say 6 degrees or less) means that as condensation collects it doesn't run down the roof slope it stays put until a drip forms which drops on to your stored belongings below. The corrugations in the roof mean that condensation tends to build flow down from the steep part of the corrugation on to the bottom and then if the roof pitch is shallow it forms a drip.

With a steep pitch air can flow up to the ridge and escape so dispersing the humidity. Any moisture forming wont form drips in the building but drain down to the eaves (and hopefully out of the building).

Keep the inside of the shed dry

Although the main source of moisture is from the air itself. If a shed is built on a concrete surface or on bare earth then water evaporating from the ground can increase humidity. The best method to stop this is to cut-off the water supply.

Methods for 'cutting off the water supply' include:

Sheds with an integral base. This effectively stops air/moisture from below getting into the shed.

Constructing a raised shed base. This lifts the shed off the ground and allows air to flow underneath the shed thus breaking one path for moisture to get into the shed.

Insulation

The reason why condensation forms on the metal roof is that it's temperature is below the dewpoint of the internal air. By adding insulation to the internal surface of the metal then the dewpoint is less likely to be met. Whatever insulation you use needs to be closely bonded to the metal.

Two common types of metal roof insulation are:

Sprayed insulation. This can be expensive and messy but reportedly effective

Thin sheets of insultation bonded to the underside of the roof. This needs to be completedly bonded (like wallpaper) so that there are no gaps. This is slightly more difficult with a corrugated metal roof than a roof made of a flat sheet of metal. But neither are beyond the reach of most people, you just need to take time to do it 'properly'.

Anti-condensation layer

The final method of stoppoing a metal roof sweating is to bond an anti-condensation layer on to the underside of the roof. This method works as a kind of buffer. When condensation starts to form on the underside of the roof it is absorbed by the fleece material. Then as the temperature inside and outside equalise the moisture is released. No drips are formed. This method doesn't actually stop the condensation forming. But the droplets in the fleece store the water and stop the drips forming.

So there we have the five methods of preventing a metal roof sweating

Let's apply them to a practical example to see which of these features are present and how the shed performs.

The shed I know best in this regard is my Asgard Flexistore.

It is a relatively small shed 1.5 x 1.2m with a pitched roof of flat (not corrugated) steel. Lets see how it gets on in regards to the five points mentioned above.

My Asgard Flexistore

My Asgard Flexistore

Roof ventilation - The shed has slots at eaves level on both sides and also vents at ridge level on both sides of the gable ends. Box ticked

Roof pitch - The roof slopes at 12.5 degrees and is not corrugated. As the roof is not 'flat' i.e. less than 6 degrees we can consider this box ticked.

Keep the inside of the shed dry - The shed has an integral steel base. No water from the ground is getting in here! The only source of water is from the air and also when I put away damp garden tools. This moisture evaporates over time with the humidity escaping through the vents. Box ticked.

Insulation - There is no insulation

Anti-condensation layer - no

Detail of front gable vent from outside of shed

Detail of front gable vent from outside of shed

Detail of rear gable vent from inside shed. Note small condensation on roof. This was taken on a cold morning and the condensation was due to my breath.

Detail of rear gable vent from inside shed. Note small condensation on roof. This was taken on a cold morning and the condensation was due to my breath.

Detail of vent at eaves.

Detail of vent at eaves.

So with three out of the five boxes ticked, how does this shed perform?

It is mainly used for the storage of garden tools but the contents stay dry and I have noticed very little if any moisture condensing on the roof. So overall a good performance.

So the shed does well for me storing outside type tools. But possibly not so good for paper or electronic equipment.

Moisture Resources

- Stop Shed Condensation – why metal roofs drip more than timber

- Shed Moisture Control – the bigger moisture picture in cold sheds

- How to Measure Humidity in a Shed – confirm if moisture levels are excessive

- Ventilating a Shed – airflow to reduce roof-surface condensation

- Shed Dehumidifier vs Heater – when heat or drying helps

- Foil-Backed Bubble Wrap Condensation Issues

Keep in touch with our monthly newsletter

Shed Building Monthly