All Shed Roofing Systems Must Meet These Criteria:

To choose an appropriate shed roofing system there are three important factors to consider:

- Durable - Resistant to high winds and rain

- Economic lifetime cost - Don't just look at the initial cost, determine the price per year (including installation)

- Appearance - pleasing to the eye

1. Durable

The primary purpose of a shed roof is to protect you and your possessions from strong winds and water penetration. To make a roof waterproof, the roof pitch and roof style will strongly influence the materials you choose.

The pitch of your shed roof can be classified into one of three broad groups:

Flat roofs: Pitch = 0 to 10 degrees

Roofs with a pitch below 10 degrees are known as 'flat roofs'. For a shed with this type of roof bitumen mineral felt on plywood decking or sheet metal will be the main options.

Flat roofs have experienced problems over the years with leakage and durability. The main reason being is that water is not 'encouraged' to drain off the roof.

In answer to the question do flat roofs leak? There is a saying in the building industry that there are only two types of flat roof. 'Those that leak.....and those that are going to leak.'

Whatever you do, don't use a 'dead flat' roof (pitch = 0 degrees). Make the roof slope at least six degrees to ensure some positive drainage. Also if the roof is insulated include a ventilated air gap between the insulation and roof deck to prevent condensation.

Low pitch roofs: Pitch = 10 to 20 degrees

Tiles or shingles may be used for roofs with these slopes with caution. Extra care must be taken with waterproof underlay and following the manufacturer's recommendations.

Pitched roofs: Pitch = 20 degrees +

Concrete interlocking tiles are really the only tile suitable at a 20-degree pitch. They are rarely used on small timber structures due to their heavy weight, large size and unattractive appearance.

Clay tiles in contrast, particularly handmade ones make for a roof with a lot of character. However, clay tiles need a minimum pitch of about 35 degrees.

Whatever product you end up using get the manufacturers' datasheets. These should state the least roof pitch at which it will remain waterproof.

Some Local Authorities recommend you add an extra 5 degrees onto the manufacturer's minimum roof slope to ensure water tightness.

|

To clarify the reason for all this talk about least roof pitches. There is a popular misconception that water only flows downhill! This is not true. At roof level, gusts of wind blow films of water upwards...defying gravity! The film of water then gets blown uphill between the overlapping tiles and into the roof structure beneath. This is why, for any particular roofing system, there is a minimum pitch for which water tightness can be assured. Also, remember that clay tiles, as well as being waterproof, also act as a hard outer layer protecting the underlayment below. The underlay is waterproof and acts as a backup system. Without the clay tiles protecting it from UV degradation, water, abrasion etc the underlay would only have a three-month life. |

Tip: When deciding the pitch of your storage shed roof, you can't go too far wrong by making it the same as your house. This has two advantages;

- It should blend in

- Hopefully, you know that the pitched roof of your house does not leak

2. Economic - What is the cheapest life time cost?

When it comes to the cheapest way to roof a shed there are two ways of looking at things:

The first is to choose the very cheapest material on a square metre basis. For this approach the cheapest shed roof material will be traditional shed roofing felt.

However you will soon find (after a year or two) that it doesn't last very long and you are having to dig into your pocket again to buy more materials and spending the weekend fixing your shed roof.

Use the benefit of my experience for your roofing project and go straight to option 2.

-

The second option is to combine the price of shed roofing materials and divide it by the expected lifespan. This will give you an estimated cost of each shed roofing material per year.

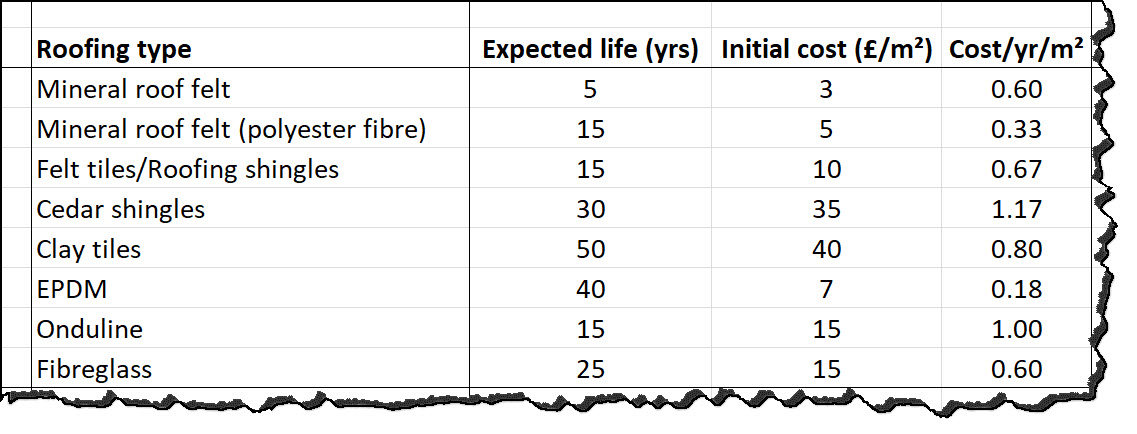

The only problem is to work out roughly how long a particular shed roofing material will last. You don't need to worry about any of this as I have put together a table below with both an estimated lifespan for a variety of shed roof coverings along with an estimated cost.

I've even done the division for you, so you can quickly scan the table and see which shed roof option works best for you.

At the moment it looks like EPDM rubber is the best option when looking at the whole life cost.

- The prices shown are estimated material costs (in GBP)

- Cost does not include the labour cost of installation

- Building material costs vary widely within a country (never mind throughout the world)

Read this table as it is intended - a guide to your further research.

The above table just includes for material costs. This means that there is no allowance for your time, or you paying someone, to replace the shed roofing material when it reaches the end of its life.

If you are paying for labour as well, options such as the EPDM roof become even more attractive as it is so durable that you will need to replace the shed before the roofing material becomes worn out!

Also remember that the visual appearance of the shed is an important factor. Your shed will be a major part of your garden for years to come and it should be pleasing to the eye.

The reason most sheds have a roof covering of bitumen mineral felt is that it has the lowest initial cost. In my opinion, if you are going to the trouble of building your own shed, it is worth investing in a more durable roof covering.

Sheds have a small roof area so any increase in cost will be small.

The key factor to consider when choosing a shed roof covering is the cost per year

Mineral felt is the cheapest material in initial cost but the most expensive on a per year basis. And that doesn't even include the labour for re-roofing the shed every 5-7 years.

Also, the benefit in the appearance of using a more characterful material will give you much more satisfaction over the years. As well as fewer weekends spent repairing the shed roof.

3. Appearance

A shed with an ugly roof will detract from your visual enjoyment of the structure. A shed roof can be an item of beauty.

If you carefully select your roof materials. You can make a waterproof, economic roof that is also beautiful.

Beauty is definitely in the eye of the beholder. But it has been my observation that the most appealing sheds often use roofing shingles.

Wooden shingles or clay tiles are really 'where it is at' in respect of craftsman-style roofs. A modern and increasingly popular alternative is the green or living roof.

Green roofs utilise low-maintenance plants, which grow in a substrate on top of the waterproof membrane.

Take a look at this variety of summerhouse roof coverings to see how similar roofs can look quite different when the only change is the type of material used to cover the roof.

Plain roofs of mineral roofing felt are really for utility sheds which are hidden away. You are much better than that ☺.

Your 12 Most Common Shed Roofing Options

Now you have a good idea of of what is expected of shed roofing material I briefly discuss each one below with their expected costs and lifespans.

Click on the link below to go the description of one of the common shed roof materials. Or just browse down the list to find out about the comprehensive list of materials that you could use for your roofing project.

- Mineral roofing felt

- EPDM Membranes

- Green roofs

- Onduline (Corrugated bitumen sheet)

- Sheet Metal Roofing

- Asphalt tiles or roofing shingles

- Wooden shingles

- Clay tiles

- Eco Slate

- Fibreglass

- Tarpaulin

- Damp Proof Membrane

Single ply shed roof coverings

Corrugated shed roofing sheets

Shed roof tiles

Temporary Shed Roof solutions

1.0 - Mineral Roofing Felt

The standard garden shed roof covering is cheap mineral roofing felt. This system does the job of keeping the water out but is fragile and relatively short-lived. A bit of unseen damage to the shed roofing will allow water in, and cause damage to the structure of the shed. A size of either roll roofing material is 1m wide and 10m in length.

Read more about using shed roof feltStandard shed felt is formed of bitumen impregnated fibres, is supplied on a roll and lasts about 5 years. An improved version of the shed felt uses a base of polyester fibres impregnated with bitumen is more durable and lasts for up to 15 years.

The heavier duty felt costs about £5/m2 against £3/m2 for the cheap felt. The cheap felt is often supplied as standard on pre-made sheds to keep the 'sticker' price down. The longer lasting felt is then available as a very sensible upgrade.

Standard shed felt.

- Design life: 5 years

- Minimum pitch: 6 degrees +

- Rough cost /m2: £3

Polyester based shed felt.

- Design life: 15 years

- Minimum pitch: 6 degrees +

- Rough cost /m2: £6

2.0 - EPDM Roofing

EPDM membranes are a type of roofing that is supplied cut to the required size before delivery. Therefore there are no lap joints to leak!

Also the rubber membrane is glued to the roof deck and secured to the perimeter of the roof. This means that there are no nail holes to leak either!

Finally, the material remains flexible when exposed to uv light (sunlight) unlike bitumen based products which become brittle and crack, causing leaks.

EPDM rubber roofing has been used on commercial and factory building roofs for over 40 years.

It is now being promoted more extensively for sheds. It is especially suited to flat roofs but can also be used on gable shed roofs of almost any pitch. Find out more on EPDM rubber roofsFind out how easy it is to install epdm roofing on a new shed roof

Or as a replacement for a shed that needs a new shed roof covering

- Design life: 25 years

- Minimum pitch: 6-90 degrees

- Rough cost /m2: £15

EPDM is especially suited to green roofs.

3.0 - Green Roofs

Green roofs are beautiful and a good choice for those wanting an environmental roof that will last a long time. They utilise a waterproof membrane on the roof deck with a build-up of growing medium on top as outlined in this article. Modern green roofs use a relatively thin layer of growing medium that particular suits hardy succulent plants.

This article outlines a way that you can grow your own green roof plants from cuttings.

A good overview of the benefits of green shed roofs is given in this article about extensive green roofs.

4.0 - Onduline - Corrugated bitumen sheet

Corrugated bitumen impregnated fibre makes for a durable roofing system. Most likely suited to slightly larger sheds. It is durable and quite cheap. Find out more about Onduline.

- Design life: 15 years

- Minimum pitch: 15 degrees

- Rough cost /m2: £15

5.0 - Sheet Metal Roofing

Corrugated metal is widely used on larger commercial sheds and buildings. It can look complex and hard to work with for the DIY builder however this need not be the case.

Metal can be an economical and very durable option if you take some time to investigate how the various metal roofing systems work, what tools to use and the best places to buy the materials and fixings. Find out more about Metal Shed Roofing.

- Design life: 15 years (varies dependent upon exposure conditions)

- Minimum pitch: 4 degrees

- Rough cost /m2: £12-20

6.0 - Asphalt shingles

Using bitumen shingles is a good step up in quality from bitumen roll roofing. Three-tab shingles are laid starting at the bottom of the roof. The shingles overlap each other by about 150 mm, at the ridge a capping piece is used.

This roof finish is a vast improvement on using a roll of Mineral felt and is much more durable. This article explains how to roof a shed with bitumen shingles.

- Design life: 15 years

- Minimum pitch: 18.5 degrees

- Rough cost /m2: £18

7.0 - Cedar shingles

Cedar shakes can make a garden building look really special. The basic shingle roof installation process is to fix the wood shingles to battens with a layer of underlay beneath.

- Design life: 30 years

- Minimum pitch: 20-30 degrees

- Rough cost /m2: £100

See more on cedar summerhouse roofs here

8.0 - Clay tiles

Clay tiles are available in a huge range of colours, sizes and shapes. Typically the best choice is to match the style of your house or other buildings in the area.

Clay tiles give the building a sense of place and permanence. A note of caution on using clay tiles for shed roofing, they are heavy! The supporting roof and walls must be made strong enough to support them.

- Design life: 40 years

- Minimum pitch: 35 degrees

- Rough cost /m2: £80

9.0 - Eco Slate

Eco Slates are artificial slates made from recycled plastic. They are a great way to provide an attractive and very durable roof. The slates are quite realistic looking and come in three different colours red, green and grey.

I find that they work really well if you have a garden room or summerhouse that is on show and you want to look really good. They are a bit more expensive than many roofing materials but give a great look alongside superb durability.

- Design life: 50 years

- Minimum pitch: 10 degrees

- Rough cost /m2: £50

Find out more about Eco Slate here

10.0 - Fibreglass

Fibreglass is not commonly used as a shed roofing material. I only mention it as I came across this example on a fisherman's hut on a Dorset beach. It looks to me that the reason it was used was for extreme durability. The fibreglass shell would resist the winter storms and sand blasting around the beach as well as be extremely secure.

Not sure it is a thing of beauty but it should last well.

- Design life: 25 years

- Minimum pitch: 0-90 degrees

- Rough cost /m2: £35

11.0 - Tarpaulin

A tarpaulin is a great short term fix for your shed roof. I have a small stock of them in my workshop that I install on customers roofs if they contact me needing an 'emergency' shed roof fix. Such as after a period of high winds when the roof felt has blown off. The Tarpaulin doesn't look great but keeps the rain out of the shed for 2-3 weeks until the weather has calmed down and we have organised a more permanent solution.

When using a tarpaulin for your shed roof make sure it is still waterproof! Some of the cheaper tarps only last for a relatively short period of time and although they still look ok, allow water through like a sieve.

When fixing a tarp I lay the material out over the shed roof and then use 70mm screws driven in at an angle through the eyelets. With a screw at each corner of the shed and possibly an extra one along the long side.

- Design life: 2-3 weeks

- Minimum pitch: 0-90 degrees

- Rough cost /m2: £14

12.0 - Damp Proof Membrane

Using Damp Proof Membrane is probably the cheapest way of making a shed roof waterproof in the short term. Damp proof membrane is made from 1200 gauge PVC, so is approximately xmm thick. As it is designed for use underneath buildings it is quite tough and it will stretch a bit to overcome irregularities in a roof surface.

PVC isn't hugely UV resistant so after a year or two it will become brittle and crack. Consequently, I haven't put a huge amount of thought into the best way to secure it on a roof. I have used this solution for a couple of customers who needed a quick, but short-term, method to keep the shed roof and contents dry while they developed their thoughts as to their longer term shed requirements.

In the example picture I simply laid the DPM out over the shed roof and fixed a timber batten on the two bottom edges and then the gable boards on the end of the shed. This has always proved sufficient in the cases I have come across. Though I suspect it might not be super durable in very strong winds. As a short term, cheap fix, it works very well.

- Design life: 6-18 months

- Minimum pitch: 0-90 degrees

- Rough cost /m2: £0.7

Conclusion

Understanding the properties of each shed roofing material should help you to find an appropriate roofing solution that matches your situation. One that will effectively enable your garden building to protect your stuff from highwinds and driving rain for many years to come.

Related posts:

- Did I say why EPDM roof membranes are so good?

- How to install felt roof shingles

- Had you considered a metal shed roof?

Keep in touch with our monthly newsletter

Shed Building Monthly